Saksham Industries is the leading Rotary Dryer manufacturers in Pune, suppliers and exporters in Pune, offering it for industrial uses. Our business model is centered on providing superior products with outstanding customer service and tailored solutions for industrial efficiency and sustainability and productivity improvement in different industries.

Rotary Dryer Suppliers and Exporters in Pune

Our organization as rotary dryer manufacturers in Pune has been motivated by constant innovation combined with unwavering quality emphasis and constant pursuit of exceeding industry benchmarks. Our aim is to provide top-quality economical rotary dryers to clients who get timely delivery within their indicated time frames.

About Rotary Dryer

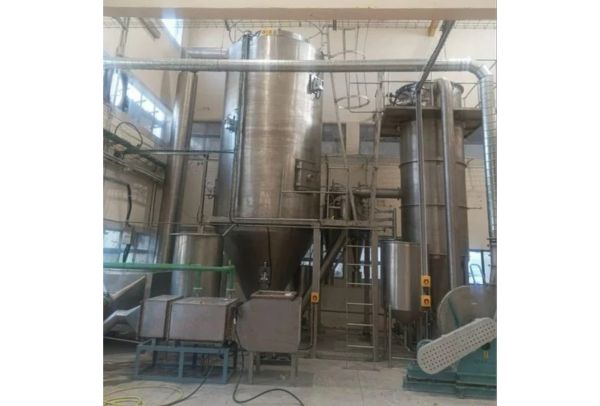

Rotary Dryer is a directly operated consecutive contact dryer with a slowly rotating cylindrical shell that is inclined to the horizontal a few degrees. There are hot gases passed through the wet material either from an external furnace or some other readily available source. Wet feed is fed at the top end of the dryer, from which it moves along the dryer under rotation, head effect, and shell slope, while dry product is withdrawn at the bottom end. Depending upon the characteristics of the processed material, the flow of gas within the cylinder would predominantly be Co-Current or Counter-Current flow.

Types of Rotary Dryers:

We, rotary dryer suppliers in Pune, provide various types of it to suit the specific requirements of diversified applications. Some of these types are given below:

- Silver Rotary Dryer: These silver rotary dryers have a cylindrical shell that rotates and dries materials fed inside a rotating drum, and porous air passes through and evaporates moisture with the drum's continuous rotation for uniform drying and greater material handling. Such dryers are ideal for drying of granular or free-flowing materials-like minerals, sand, or even agricultural products. The term silver could be the construction material of the whole dryer or even a brand name, but the basic work principle is similar.

- Industrial Dryer: An industrial dryer machine functions as a diverse machine set that removes moisture from various procedures while using convection and conduction, and radiation drying techniques based on the material requirements. Such industrial equipment is essential in food processing and pharmaceutical production, and manufacturing, plus other industries that need precise moisture control. Drying machines utilize designs that span from easy, simple hot-air ovens to complex continuous systems.

- Continuous Dryer Machines: A continuous dryer machine is designed, in fact, for uninterrupted operations and so can process material in high volumes. It should be a steady flow through the drying chamber, which guarantees uniformity and consistent product quality and throughput. It will be necessary for those industries whose production is continuous, such as chemical processing, food manufacturing, or paper production.

Technical Specifications of Rotary Dryer:

We are the best rotary dryer suppliers and exporters in Pune and provide a technical sheet for more clarification and details!

| Specifications |

Silver Rotary Dryer |

Industrial Rotary Dryer |

Continuous Rotary Dryer |

| Capacity |

200 Ton/hr |

Depend on model |

200 Ton/hr |

| Automation Grade |

Automatic |

Semi-Automatic |

Automatic or Semi-automatic |

| Heating Source |

Coal |

Material |

Coal |

| Material Used |

Stainless Steel |

Mild Steel |

Stainless steel |

| Surface Finish |

Coated |

Polished |

Polished |

| Output Power |

3 kW |

2-4 kW |

3 kW |

| Speed |

3200 RPM |

3000 RPM |

NA |

| Power Source |

Electric |

Electric |

Electric |

| Usage |

Industrial |

Industrial |

Industrial |

Key Features of Rotary Dryer:

As rotary dryer manufacturers in Pune, we produce these dryers to ensure numerous features that can improve their performance and efficiency. Some of these features are mentioned below.

- High Thermal Efficiency: Our rotary dryers can expel moisture very efficiently via direct or indirect heating from the material. This design supports efficient heat transfer and thus diminishes energy consumption, further conducting significantly the drying operation itself. The application of advanced combustion systems or heat recovery methods will provide additional efficiency.

- Continuous Operation: The rotary dryer operates continuously, an important consideration for operation in high-volume applications, whereas batch dryers are only semi-continuous. Thus, one can maintain an uninterrupted schedule by minimizing downtime; hence, productivity reaches peaks with a steady flow of dried material output that really fits large-scale industrial applications.

- Customizable Design: These rotary dryers can be designed according to the specific materials, including customizable drum sizes, retention times, and heating methods. The integration of flight and lifting designs, along with sophisticated operating systems, represents ways to boost drying performance targeted at different industries.

- Versatility: The driers operate effectively with all types of materials, extending across minerals and biomass in addition to fertilizers and food products, and chemicals. These dryers serve essential functions for industries that need efficient bulk solid and paste drying capabilities because they have built-in versatility.

Applications of Rotary Dryer:

Our company, which operates as a local rotary dryer exporter in Pune supplies these drying machines for several industrial uses.

- Rotary dryers supplied by our company serve the mining sector extensively to dry ores, along with minerals and aggregates.

- The drying equipment operates for both agricultural materials and biomass products, including grains and corn alongside soybeans and different bio-based materials like wood chips together with sawdust, and bagasse.

- The rotary dryers dry multiple food products, including powdered milk as well as coffee and spices, and fruit pulps during food processing. Current rotary dryers perform selective moisture removal owing to their ability to preserve flavours together with original product textures.

- The rotary dryer provides sustainable drying operations for chemical powders as well as pharmaceutical compounds and salts, and fertilizers.

- The drying process at cement plants using rotary dryers improves the efficiency of limestone and slag transformations for construction materials.

Being the renowned Rotary Dryer manufacturers, suppliers and exporters in Pune, at Saksham Industries, we are dedicated to offering our customers the highest quality and service. We employ only the finest materials and parts in our products, and our skilled engineers and technicians ensure that every product conforms to our rigorous quality standards. We also offer complete after-sales service to make sure that our customers are content with their purchase. Contact us.