Rotary Dryer Suppliers and Exporters in India

We have expertise in manufacturing, supplying, and exporting rotary dryers across India. Our dryers help industries optimize productivity, reduce energy costs, and maintain tight moisture tolerances. Applications range from mineral drying in mining to biomass processing in renewable energy and food‑grade drying in pharmaceuticals and spices.

With over 500 satisfied clients, we lead the market as premier Rotary Dryer Manufacturers in India and trusted Rotary Dryer Suppliers India. Contact us today to discuss your drying challenges and request a quote - our team will tailor a solution that boosts your ROI while ensuring regulatory compliance.

What Is a Rotary Dryer?

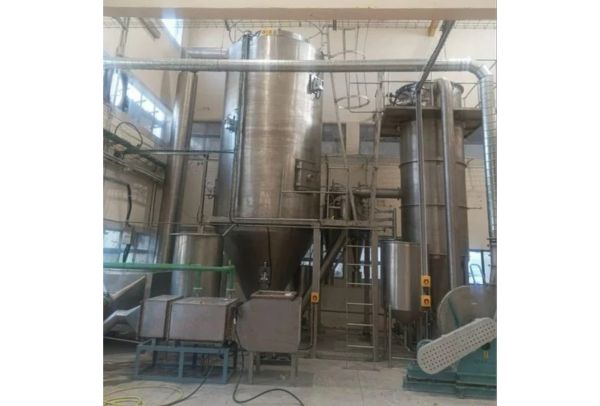

A rotary dryer is a heat transfer machine consisting of a rotating drum, an internal flight system, and a hot‑gas circulation loop. It uniformly dries bulk materials by tumbling them in a hot air stream, ensuring consistent moisture levels.

In India, rotary dryers must meet product standard certifications like ASME Section VIII Division 1, Indian Standards (IS), British Standards, PED, and API‑660, among others. For safety, our designs comply with IBR, DNV, TÜV, and other recognized inspection agencies, guaranteeing stable operation under high temperature and pressure conditions.

Technical Specifications of Rotary Dryer

We are the best rotary dryer suppliers and exporters in India and provide a technical sheet for more clarification and details!

| Specifications |

Silver Rotary Dryer |

Industrial Rotary Dryer |

Continuous Rotary Dryer |

| Capacity |

200 Ton/hr |

Depend on model |

200 Ton/hr |

| Automation Grade |

Automatic |

Semi-Automatic |

Automatic or Semi-automatic |

| Heating Source |

Coal |

Material |

Coal |

| Material Used |

Stainless Steel |

Mild Steel |

Stainless steel |

| Surface Finish |

Coated |

Polished |

Polished |

| Output Power |

3 kW |

2-4 kW |

3 kW |

| Speed |

3200 RPM |

3000 RPM |

NA |

| Power Source |

Electric |

Electric |

Electric |

| Usage |

Industrial |

Industrial |

Industrial |

Types of Rotary Dryers

- Silver Rotary Dryer: Silver rotary dryers feature a rotating cylindrical shell made of stainless steel. As the drum spins, porous air passes through the bed of material, evaporating moisture uniformly. Ideal for minerals, sand, and agricultural products, these dryers deliver consistent throughput and ease of maintenance.

- Industrial Rotary Dryer: With convection, conduction, and radiation heating options, industrial rotary dryers cater to food, pharmaceutical, and chemical sectors. They range from simple hot‑air ovens to complex continuous systems, offering precise moisture control and modular integration into existing lines.

- Continuous Dryer Machine: Designed for uninterrupted operation, continuous rotary dryers handle high-volume processing with a steady feed and discharge. This ensures uniform drying, improved throughput, and minimal downtime - critical for chemical processing, paper production, and large‑scale food manufacturing.

Applications of the Rotary Dryer

- Mining & Minerals Rotary dryers remove moisture from ores, aggregates, and mineral concentrates. They improve handling characteristics and downstream processing efficiency in mining operations.

- Biomass & Agricultural Products From grains and oilseeds to wood chips and bagasse, rotary dryers deliver precise moisture reduction, preserving nutritional value and enabling further processing in biofuel production.

- Food Processing Coffee beans, spices, powdered milk, and fruit pulps are gently dried to retain flavor, color, and texture. Trace moisture control prevents spoilage, ensuring product quality in the supply chain.

- Chemicals & Pharmaceuticals Drying chemical powders, salts, and pharmaceutical compounds demands tight moisture tolerances. Our dryers support GMP‑compliant designs with clean‑in‑place (CIP) options and inert gas circuits for sensitive materials.

- Cement & Construction Materials In cement plants, rotary dryers prepare limestone and slag by removing surface moisture. This enhances kiln efficiency and reduces energy consumption in clinker production.

How Rotary Dryer Works

Rotary dryers operate by continuously feeding wet material into a slightly inclined rotating drum. As the drum turns, internal flights lift and cascade the material through a hot air stream. Heat transfer occurs via convection between the air and the material, while conduction takes place as material contacts the drum shell. Exhaust fans then remove moist air, maintaining a controlled drying atmosphere. This simple yet effective design ensures uniform drying and high throughput.

Rotary Dryer Ordering, Compliance, and Safety Information

When you order a rotary dryer from Saksham Industries, you gain:

- Compliance: with ASME, IBR, PED, API, and TEMA standards.

- Safety Features: like high-temperature limit switches, pressure relief devices, and emergency shutdown circuits.

- In-house Testing: including hydrostatic, pneumatic, radiographic, ultrasonic, magnetic particle, liquid penetrant, and PMI inspections.

Contact Details

- Address: Gat No. 285 Nanekarwadi, Chakan, Taluka Khed, Pune - 410501, Maharashtra, India

- Phone: +91‑9850751781

- Email: info@sakshamindustries.in

For turnkey installation, we provide detailed drawings, on‑site supervision, and operator training—ensuring your plant meets all regulatory requirements.

Why Choose Us?

- Expertise and Experience: With over 20 years in process equipment industries, our engineers design dryers optimized for your material and throughput requirements.

- Industry Compliance: We collaborate with Lloyd’s, TUV, BV, DNV, Technip, SGS, ABS, Bechtel, and IBR to ensure every dryer meets global safety and quality standards.

- Customized Solutions: From drum diameter to flight configuration and heating source, we tailor every detail for optimal performance and energy efficiency.

- Quality Assurance: Our dedicated QA team conducts multi‑stage inspections and non‑destructive testing to guarantee product reliability.

Because of these strengths, we are the foremost Rotary Dryer Manufacturers in India and trusted Rotary Dryer Suppliers India.

The Saksham Industries is your trusted Manufacturer, Supplier, and Exporter of rotary dryers in India. Moreover, we support on‑site installation, commissioning, and after‑sales service to ensure seamless operation of your drying line. Request a Quote or Contact us and discover how our rotary dryers can transform your process efficiency.