Capabilities

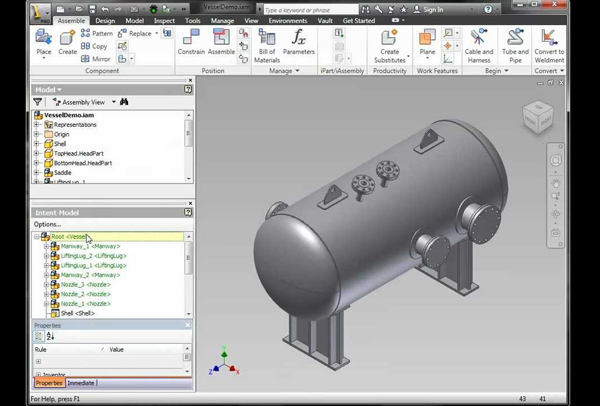

Design

The design team is well equipped with technical and functional expertise to give you the most efficient designs in accordance with National and International standards and Code. Our facility also provides the infrastructure to optimize the efforts and get measurable outputs. Design tools are used by team considering all aspects of design to enhance the actual performance of the products.

Software

- PV Elite (Latest Version) – Mechanical design for heat exchangers & pressure vessels.

- AutoCAD Mechanical (Latest Version) – Design drafting package

Codes and Standards

- ASME SECTION VIII DIVISION 1

- BRITISH STANDARDS

- INDIAN STANDARDS

- TEMA

- PED

- API-660

- Naval Engineering Standards

- IBR

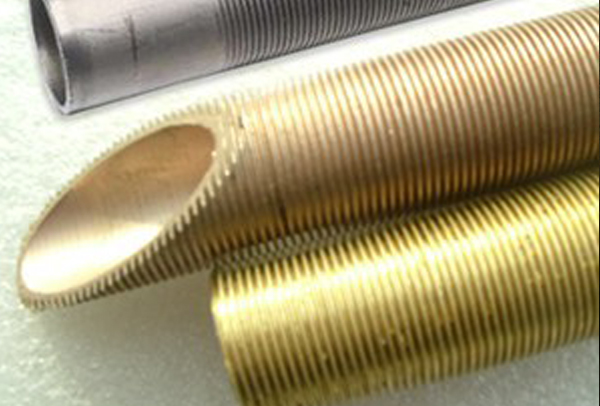

Material we use

- Low temperature steels

- High yield point carbon steels

- Stainless steels & Duplex Stainless Steel

Quality

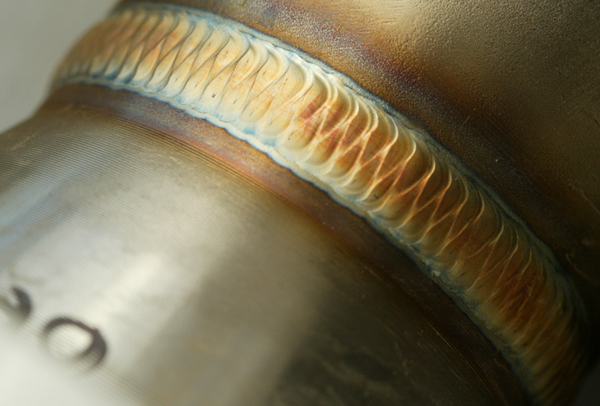

All our products have ISO, ASME U,R,NB regesrations which assures the end users that our products are safe, economical and effective.We buy the material required for our product of best grades from reliable vendors, thus ensuring quality right from the start.

Welding

- GTAW - Gas Tungsten Arc Welding

- FCAW - Flux Core Arc Welding

- SMAW - Submerged Metal Arc Welding

- SAW - Submerged Arc Welding

Non Destructive Testing

- Radiographic testing.

- Ultrasonic testing for raw material and welds

- Magnetic particle testing

- Liquid penetrant testing.

- Visual Inspection

In-House Tesing Facility

- Non Destructive Testing

- Hydrostatic Testing

- Pneumatic Testing

- PMI Testing

Manufacturing

A total area of 20,000 sq.ft is developed with all aspects like EOT crane, concrete flooring, marking, segregation of work flow and another 20,000 sq ft area is kept open for loading purpose of heavy and vessels or heat exchangers.This set up allows us to work with best tools and concentrate on the quality of the products delivered.Test pit of size 6 meter long, 3 meter wide and 2 meter deep for pneumatic pressure testing of vessels is provided on the shop floor. This is an uncommonly provided facility for safe pneumatic pressure testing.

Material Handling

- EOT Cranes

- 10 Ton, 12.5 Ton, 25 Ton Capacity

- Motorized Rollers

- 50 Ton Capacity

- Installed Capacity(200 KVA)

- DG Capacity(65 KVA)

- Inhouse Packing and Forwarding

Machinery and Equipments

| Sr.No | Machinery / | Capacity/ Range | Qty |

|---|---|---|---|

| 1 | Plates rolling machine with pre pinching facility | 30(T) x 2500(W) mm Make- Himalaya | 1 No |

| 2 | Radial drilling machine | Up to 80mm Dia hole | 3 Nos. |

| 3 | Hydraulic Press Machine | 300 Ton (Up to 30mm Thk) |

1 No. |

| 4 | Lathe | 6 Feet | 2 Nos. |

| 5 | Welding rectifier with pulse TIG welding | 400 Amp | 8 Nos. |